Jet engines are so expensive, because they are getting more and more sophisticated and fuel efficient.

Some engines are reliability wonders, have logged between 30 000 hours up to 50 000 hours time on wing without having to visit the engine workshop.(CFM56)

They are so reliable, it is very difficult to shut them down, as has been seen on the QF32 accident. (Trent 900)

After landing the A380, the controls to shutdown the engine were not working. Firefighters tried for hours to shutdown the number 1 engine without success.

First they used a massive quantity of water but the engine was still working. Only after spraying big amounts of foam into the engine it did shutdown.

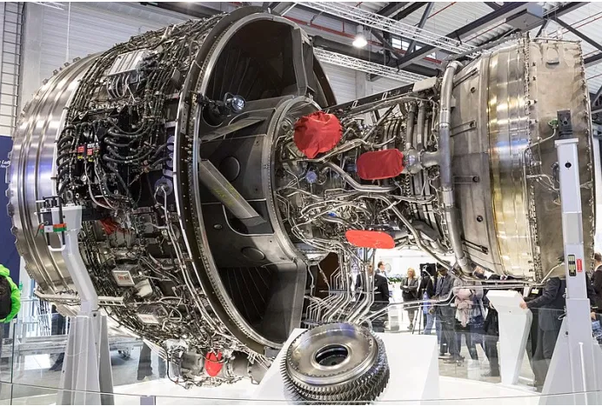

This is the most modern and efficient long-haul engine in the world, the Trent XWB. The complexity is mind-boggling.

In order to gain a percentage of fuel efficiency, engine makers use highly ingenious techniques.

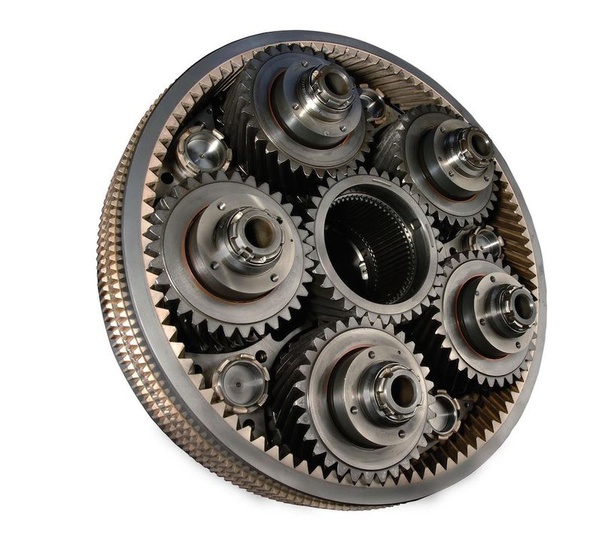

Like the Geared Turbo Fan(GTF) which uses a clever planetary gear design to uncouple/reduce the speed of the fan from the core.

It took Pratt and Whitney almost 20 years to develop this technology and went almost bankrupt.

The fan blades are either made of a titanium alloy(hollow inside to save weight) or carbon fiber. A single one can cost as much a middle class car.

Only three companies in the world have enough experience and the means to produce such engines. Rolls-Royce, General Electric, Pratt and Whitney.

The development of this engines, needs a huge investment/risk and technical prowess.

But airlines always demand more fuel efficiency, lower maintenance costs and reliability.

To guarantee a steady progress, this companies invest billions into R+D.

Rolls-Royce was once at the brink of bankrupcy when they developed the triple spool design.

A new engine has to be rigorously tested to achieve certification.

Manufacturers blow engines up, shoot birds into it, water ingestion tests and so on..

Blade ingestion test Trent 900.

Author – Michael Schneider