The purpose of torque loading is to make sure the correct and efficient clamping together of two surfaces.

This prevents #over-stressing, distortion, and shearing of bolts, studs, nuts etc.

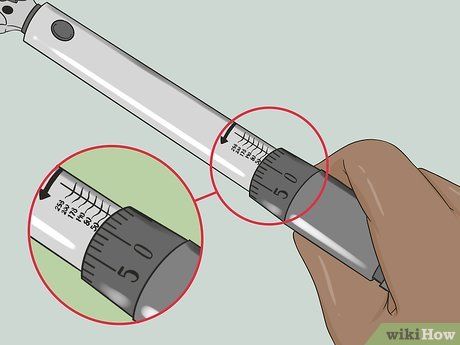

Torque load_values are normally determined by friction, type of thread, material, lubrication and finish of the surfaces of the fasteners.

Before even start to use torque wrench make sure All torque wrenches that are used on aircraft are regularly inspected,

tested and calibrated by a facility equipped to do so.if the serviceable tag indicates as expired. DO NOT USE THE TOOL.

Aviation bolts and screws without the proper torque can fail in a number of ways. First, if they have not received enough torque, they can loosen under vibration and come free.

Not only do they then fail to hold their load, they also become foreign object debris and may cause significant damage as they rattle around.

vibration is such an important factor in aviation that every bolt which is not fastened with a self-locking nut must also be safetied, usually with wire, to prevent it from vibrating loose.

Can also fail from having received too much torque. Over-torquing can deform the fastener, the substrate or both. This will hashtag weaken the fastener or substrate, rendering it more likely to fail.

Aircraft bolts are subject to multiple high stresses, including shear force, tension force, vibration, and expansion/contraction due to temperature changes. This makes them likely to fail when used in conditions beyond their rating.

Author – Neranjan Danthure Bandara